- Linii productie geam termoizolator

- Producator Han-Jian utilaje complexe cu insertie automata gaz automate

- Inaltime linie inter 1600 3300 mm

- Dimensiune maxima geam termopan cu 2 si 3 geamuri

- 1.Linie productie geam termoizolator automat(pentru Low-E, geam tripan si functie de umplere cu gaz)+ masini aditionale

- 1.Linie productie geam termoizolator, procesare perfecta geam low-e,umplere automata gaz, functie cinstructiva automata cu 2 s-au 3 geamuri

- 2.Robot sigilare geam termoizolator sistem dual bicomponent sigilare, pompade mixaj

- Utilaje adiacente

- 1. Masina automatade indoit baghete ,cu control plc pentr interfata

- 2. Masina de incarcareautomata cu silcagel

- 3. Extruder butil ,cu ajustareautomata pentru diferitele grosimi de baghete automata

- 4. Masina de taiere distantier

- 5. Sistem de tratarea a apei

- Optiuni

- 1. Masina de slefuire verticala a geamului low-e seaming-cu 6 axe

- 2. Sistem de incarcare descarcare automata

- Click aici pentru video

- Click aici pentru Catalog Han-Jian

- Click aici pentru schema tehnica

- Click aici pentru descriere EN

Author: glasmed

Linie productie geam termoizolator automata inaltime 1600-3000 mm MM Stefiglass

- Linie productie geam termoizolator automata inaltime 1600-3000 mm MM

- Producator Stefiglass Italia

- SPECIFICATIE :

- 1. Masina de spalat-verticala-inaltime 1600-3000 mm cu 6 perii

- Cu perii pentru geam low-e ftrontale

- Grosime geam 3-12 mm

- Conveior de intrare automata 2800mm

- Conveior de iesire automata iluminata

- Cutie cu ventilator pentru reducerea zgomotului

- Fotocelule pentru dirijarea inaintari si opriri geamului

- Inaintarea geamului pe role

- Contine 3sectiuni: spalare, clatire, uscare

- 2. Zona de asamblare baghete:

- Lungime 3200 mm

- Dotata cu opritori, dirijare verticala si orizontala

- 3. Presa automata panell

- Intrare automata mm

- Presa panell- mm

- Iesire automata mm

- 4. Masa rabatabila H 1600-3000 mm

- Lungime 3200 mm

- 5. Circuit automat pentru purificarea apei-model special

- 6. Utilaj automat de demineralizarea apei cu osmoza inversa osmosy idro 60

- Click aici pentru descriere RO

- Click aici pentru schema tehnica

- Click aici pentru descriere EN

- Click aici pentru descriere IT-EN

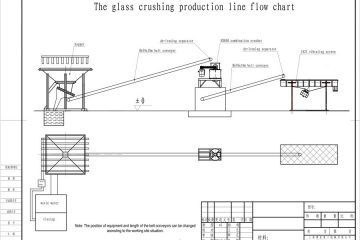

Linie concasare cioburi de sticla

- Linie concasare cioburi de sticla

- Atasat linie de concasare sticla:

- Specificatie

- Hopper silou de strangere a sticlei geamurilor cu sistem de spalare cu apa(praf, depuneri, murdarie, etichete)-recirculabil

- Conveior de incarcare cu curea-banda 18 m

- Concasor vertical cu ciocane

- Sistem de sortare cu site

- In cazul in care la concasor se creste viteza de rotatie, la 1600 minut, se poate sfarama, cioburile dupa cum urmeaza:

- 1:3;6

- Concret: se poate produce;

- – 10% particule de 0,1 mm

- – 30% particule pana la 0,5mm

- – 60% particule pana la 0,5-1 mm

- Acestea se pot separa in final prin site vibratoare

- Capacitate 5-15 t/zi

- Conveior de iesire a cioburilor maruntite 10 m

- Click aici pentru date tehnice

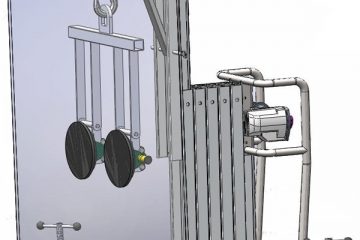

EasyLift

- TGT EasyLift

- Utilaj mic foarte manevrabil

- Cu acest utilaj se pot monta geamuri si de dimensiuni mari in spatiu de acoperis, si inaltime

- Montaj usor al utilajului

- Extrem de mobil

- Dimensiune 1000x500x500 mm

- Greutate proprie 45 kg

- Greutatea pe care o poate ridica 120 kg

- Inaltimea la care poate ridica 4200 mm

- Manevrabil electric

- Cu 4 ventuze

- Are 4 bucati suporti telescopici

- Click aici pentru date tehnice EN

CombiLift H6

- CombiLift H6

- Sigur, compact

- Comprima 3 utilaje intr-un utilaj

- Potrivit pentru ridicari, pentru montaj vertical si acoperis pana la o inaltime de 6 m

- Varianta cu actionare electrica

- Geutate proprie 168 kg cu contragreutati

- Dimensiune 1880x790x1780 mm

- Greutatea pe care o poate ridica 300 kg

- Inaltimea la care poate ridica 6000 mm

- Click aici pentru date tehnice EN

Masina de slefuit simpla orizontala la banda BR 230

- Masina de slefuit simpla orizontala la banda BR 230

- Cu rola de lucru, diametrul 230 mm

- Banda 1830×100 mm

- Viteza banda 12,4m/sec

- Dimensiune masa de lucru 640×2400 mm

- Click aici pentru video

- Click aici pentru video 2

- Click aici pentru descriere tehnica EN

Masina de gaurit orizontala cu 2 capete-opozabile VS-75

- Masina de gaurit orizontala cu 2 capete-opozabile VS-75

- Gaura se realizeaza cu 2 capete-burghie de gaurit din partea superioara si inferioara

- Dimensiune gaura 4-100 mm

- Grosime geam 3-20 mm

- Click aici pentru video

- Click aici pentru descriere tehnica

Masina de gaurit vericala VSV 100

- Masina de gaurit vericala VSV 100

- Cu 2 capete

- Gaura diametru 3-100 mm

- Grosime geam 3-20 mm

- Adancimea de realizat gaura de la margine 900 mm

- Viteza de rotatie motor 500-1400 rotatie/minut

- Click aici pentru video

- Click aici pentru descriere EN

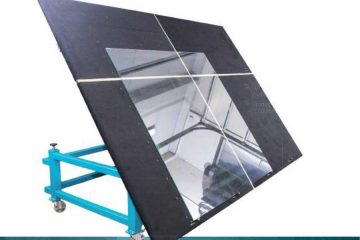

Masa de taiere hidraulica manuala, rabatabila, cu perne de aer Ful 4

- Masa de taiere hidraulica manuala, rabatabila, cu perne de aer Ful 4

- Grosime geam 3-19 mm

- Poate fi livrata in 2 variante:

- Dimensiune maxima geam 2000×2800 mm

- Dimensiune maxima geam 3200×2500 mm

- Click aici pentru video

- Click aici pentru video 2

- Click aici pentru date tehnice EN

Utilaj Express 350CW

- Utilaj Express 350CW

- Descriere Engleza

- Lifting capacity 350 Kg (770 Lbs)

- 1-2 man operation

- Ideal for glazing in small confined areas

- Vacuum head can be tilted, rotated and side shifted

- Battery operated rear tug

- Moves glass over uneven ground on site

- 4 x 300mm (12″) adjustable and flexible vacuum cups

- 1 or 2 fully independent vacuum systems

- Glass can be swivelled to the side for transport through small doors

- Battery powered vacuum system

- Easily transported inside a van and assembled

- Fully counterweighted machine

- Patent pending

- Options:

- 2nd battery powered vacuum system

- Click aici pentru video